What are the principles and technologies of 3D printers?

【3D printer principle|3D Printer technology 】3D printer basically uses or uses itself to use or use itself to use printing technology materials such as photosensitive 3D Printer principle technology is believed to be FFF/FDM 3D printing technology, but in fact 3D There are many types of printing technology, including DLP 3D printing technology, SLA 3D printing technology, Binder Jetting 3D printing technology, SLM 3D printing technology, etc. Each 3D printing technology and principle has its own characteristics. This time I will introduce them one by one.

What are the principles and technologies of 3D printers?

Currently, the main 3D printing technical principle types:

• FFF (FDM) 3D printer principle technology

• LCD light curing 3D printer principle technology

• SLA light curing 3D printer principle technology

• DLP 3D printer principle technology

• What are the advantages of DLP over other light curing technologies?

• Jet bonding Binder Jetting (Inkjet Powder) 3D printer principle technology

• SLS 3D printer principle technology

• SLM 3D printer principle technology

• PolyJet 3D printer principle technology

FFF (FDM) 3D PRINTER principle technology

3D Printer 3D printing principle: According to the cross-sectional profile information of the product, the nozzle heats the thermoplastic linear material into a semi-liquid state, and then performs selective X-Y plane movement, and the extruded hot-melt material is rapidly cooled to form a layer of cross-sectional profile , after finishing, the workbench is lowered, and then the next layer is printed, and so on, finally forming a three-dimensional product.

The first is FDM fuse manufacturing technology (also known as FFF: Fused Filament Fabrication), this 3D Printer principle technology is widely used. The 3D printing principle of the FFF 3D printer is to heat-melt the glue filament, then extrude it from the heating nozzle, and print the object from the bottom in a layered manner, so when you take a closer look at the printed by the FFF 3D Printer principle technology Objects, you will feel that there are layers of horizontal lines on the surface of the object. The thicker the thickness of these horizontal lines, the more obvious the horizontal lines will be, and the less time it takes to print. The thinner the thickness of these horizontal lines, the less the horizontal lines will be. Obviously, the surface of the object is more detailed, but the time required for printing is relatively longer. The principles of FFF and FDM 3D printers are basically the same.

image source: thingiverse

LCD 3D PRINTER principle technology

3D Printer 3D printing principle: Using the 3D printer principle of liquid crystal screen LCD imaging, the image signal is provided by the computer program, and a selective transparent area appears on the LCD screen. The ultraviolet light passes through the transparent area and irradiates the photosensitive resin consumables in the resin tank for printing. Exposure curing, when the curing time of each layer is over, the platform support lifts the cured part to allow the resin liquid to replenish and reflow, the platform descends again, and the thin layer between the model and the release film is exposed to ultraviolet light again. As a result, it is solidified layer by layer and printed into an exquisite three-dimensional model.

The principle of LCD light-curing 3D printers is to use the UV LED lamp that emits light through the LCD screen to irradiate the resin in the light-curing resin tank. The LCD screen only allows the LED light to pass through the area to be cured to the finished part, that is to say, the LCD screen acts as a Mask and only displays Pixels needed for the current layer and blacked out the rest. Therefore, the 3D Printer principle technology of LCD is usually called “Masked SLA” or MSLA. The principle and technology of LCD 3D printer is almost the same as that of DLP 3D printer introduced later. It also solidifies a whole layer at a time, but DLP uses a projector to irradiate light instead of LED light.

image source: 3dsourced

SLA light curing 3D PRINTER principle technology

3D Printer 3D printing principle: SLA 3D Printer principle technology, full name stereolithography molding method, is to use laser to focus on the surface of light-cured material, so that it is sequentially solidified from point to line, from line to surface, and repeats itself, so that layers are superimposed form a three-dimensional entity.

Compared with FDM 3D printing technology, SLA light-curing 3D Printer principle technology (Stereolithography) mainly uses liquid photosensitive resin as the 3D printing material. When the laser is irradiated on the liquid photosensitive resin, the photosensitive resin will be transformed from liquid to solid, and finally the whole model will be will take shape. The light-curing 3D printer principle technology also prints objects in 3D in a layer-by-layer manner.

The fineness of the objects printed by the SLA 3D printer principle technology is higher than that of the FFF 3D printer principle technology, and the printed objects are also smoother. When using the principle of SLA 3D printers to produce, users need to add support to the model to support the 3D model before 3D printing.

DLP 3D PRINTER Principle Technology

3D Printer 3D printing principle: The principle of DLP 3D Printer is that the digital light source is projected layer by layer on the surface of the liquid photosensitive resin in the form of surface light, and the layers are solidified and formed.

The principle technology of DLP 3D Printer (Digital Light Processing) is very similar to the principle technology of SLA 3D Printer, and the printing precision is very high, and it is printed layer by layer like the principle of SLA 3D printer. The principle of the DLP 3D printer is to use liquid photosensitive resin as the 3D printing material. When printing, it is also necessary to add support to the 3D model as a support before printing. A little different from SLA, the DLP 3D Printing printer does not use a laser but a projector to project LED light to convert the photosensitive resin from liquid to solid. For each projection, project the shape pattern of one layer of the 3D model onto the photosensitive resin, let it solidify into one layer of the printed product, and then repeat the projection step until the entire model is printed.

image source:cadjewelryschool

The following video is the process of DLP 3D Printer principle technology:

What is the advantage of DLP over other curing light technologies?

In terms of printing speed, DLP is much faster than SLA photocuring technology, because DLP will cure a whole layer of photosensitive resin every time it projects light, that is to say, DLP will cure the whole piece when each layer is cured. The SLA laser cures the photosensitive resin point by point, so the speed of DLP is much faster than that of SLA technology. Therefore, with DLP technology, the time to print a model and print 10 identical models will be the same, while SLA requires more time. 10 times longer.

As for DLP and LCD light curing technology, their main difference lies in the type of light source. DLP uses a tiny, mirror-projection device to cure the resin, while LCD 3D printers use UV LEDs that shine through an LCD screen. These technologies also vary in printing speed and accuracy. In general, DLP technologies print faster because their light is more intense. They also perform well in terms of accuracy in printing small models, while LCD printers are generally more accurate in printing larger models.

On the other hand, since LCDs use LCD screens, LCD stereolithography 3D printers will have a shorter lifespan than DLP printers because the LCD screen must be replaced more frequently. This increases the life cycle cost of LCD printers. Also, dots of light and dead spots are defects that exist in LCD panels, while DLP does not have this problem.

Jet bonding BINDER JETTING (INKJET POWDER) 3D PRINTER principle technology

3D Printer 3D printing principle: Binder Jetting jet bonding 3D Printer principle technology uses an inkjet print head to spray the binder into the powder, so that a layer of powder is bonded in the selected area, and each layer of powder will be the same as the previous powder layer. Through the infiltration of adhesives, the three-dimensional structure of objects is produced by layering layers.

The printing materials used in Binder Jetting Inkjet Powder 3D Printer principle technology are some powder materials, and the powder is combined and formed by jetting the binder. When the adhesive print nozzle sprays the adhesive onto the powder, one of the layers of powder is bonded, and each layer of bonded powder is combined with the previous layer of bonded powder to become part of the final product. By analogy, layer by layer bonding to 3D print the entire model. In addition, according to the principle of Binder Jetting 3D printer, during the process of 3D Printing, there will be a color inkjet head sprayed on these bonded powders based on the color requirements of the model, so the principle of Binder Jetting 3D printer can be used to 3D Print full-color models.

SLS 3D PRINTER Principle Technology

3D Printer 3D printing principle: SLS 3D Printer principle, using the basic principle of high temperature sintering of powder materials under laser irradiation, precise positioning is achieved through computer-controlled light source positioning devices, and rapid prototyping through layer-by-layer sintering accumulation.

The printing materials used in SLS laser sintering (Selective laser sintering) 3D Printing technology are some powder materials, such as gypsum powder, nylon powder and so on. The principle of SLS 3D Printer is also to 3D print objects in the form of layers. The principle of the SLS 3D printer is that when the laser is irradiated on the powder, the powder is sintered or melted due to high temperature. When the powder is sintered or melted, the powder will stick together and be called a solid, and form one of the layers of the 3D printed product. When the sintering of one layer of powder is completed, the printing platform of the SLS 3D printer will descend, and then there will be a roller device to cover the new powder on the printing platform, and then the laser will sinter and melt the new layer of powder to The layer-by-layer method is analogized in this way, and finally the entire 3D model is 3D printed. The principle of laser 3D printers is basically similar.

The following video shows the process of SLS 3D Printing :

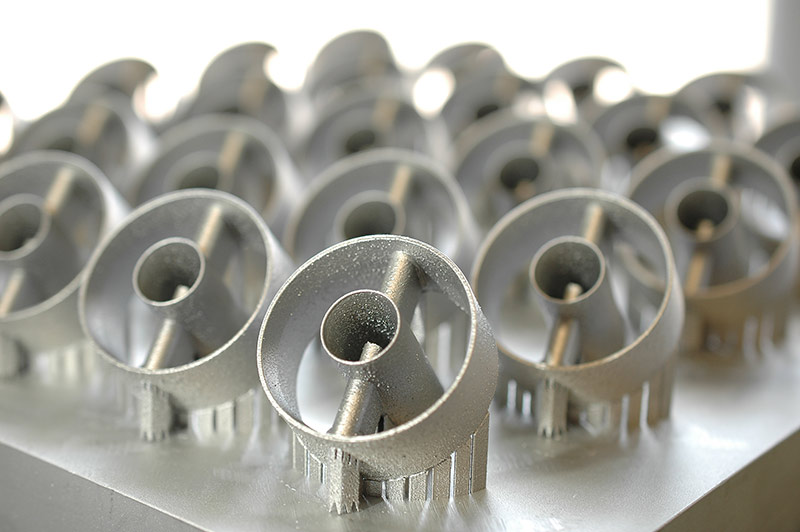

SLM 3D PRINTER principle technology

3D Printer 3D printing principle: The principle of SLM 3D Printer is a technology that uses metal powder to be completely melted under the heat of the laser beam, and then cooled and solidified to form a shape.

Similar to SLS 3D Printing is SLM (Selective laser melting) 3D Printing principle technology, their 3D Printer principle is roughly the same, but the principle of SLM 3D printer is that the 3D Printing material used is metal powder, so the temperature for laser sintering needs to be higher , to sinter the metal powder.

SLM 3D printer principles can be used to produce parts using a variety of metals and metal alloys, including aluminum, stainless steel, titanium, cobalt chrome and inconel. These materials meet the needs of most industrial applications ranging from aerospace to medical. Precious metals such as gold, platinum, palladium and silver can also be processed.

The cost of metal powder is very high. For example, the cost of one kilogram of 316L stainless steel powder is about US$350-$450. Therefore, making parts use the least amount of material and reduce the use of supports is the key to reducing costs.

A key advantage of metal 3D printing is its compatibility with high-strength materials such as nickel or cobalt-chromium alloys, which are difficult to process with traditional manufacturing methods. By using metal 3D printing to make parts in near-net shape, they can be post-machined to a very high surface finish, resulting in significant cost and time savings.

The following is a demonstration of SLM 3D Printing :

POLYJET 3D PRINTER Principle Technology

image source: stratasys

3D Printer 3D printing principle: The principle of PolyJet 3D Printer is to spray a layer of liquid photopolymer onto the build tray, and then immediately cure it with ultraviolet light. Thin layers are slowly layered into the model until a complete 3D model is formed.

PolyJet is a 3D printing technology that prints parts by jetting thousands of photosensitive polymer liquid droplets onto a build platform and curing them with UV light. It is one of the fastest and most accurate 3D printing technologies currently available. PolyJet is basically just the name Statasys gave to its material jettng MJ 3D printer. Likewise, 3D Systems calls its MJ printer the MultiJet. Names can sometimes be tricky in the 3D printing industry, with multiple names used for the same 3D printer principle technology or product. (eg FDM vs FFF or DMLS vs SLM.) The main reason is that many companies are trying to get patents. So where did the PolyJet name come from? There is a story behind this too.

In 2000, a company called Objet-Geometries developed the first 3D printer that jetted droplets of photopolymer liquid and cured it with UV light. They were developed with the development of this 3D printer principle technology, called PolyJet, and have several patents.

In 2011, Stratasys acquired the company with the goal of expanding its product range to include MJ solutions. Thus, the name PolyJet remained the same and is now used for Statasys’ printers. So, MJ and PolyJet (and MultiJet) are the same 3D printer principle technology, but with different names. Of course, since the development of the technology is between the two companies, there are some minor differences between their respective devices. However, the basic 3D printing technology principles remain the same.

3D PRINTER 3D printing principle FAQ

Q1: What are the main 3D Printer 3D printing principle technologies on the market?

Main 3D Printer 3D printing principle technology: FFF (FDM) 3D Printer principle technology, SLA light curing 3D Printer principle technology, DLP 3D Printer principle technology jet bonding, Binder Jetting (Inkjet Powder) 3D Printer principle technology, SLS 3D Printer principle technology , SLM 3D Printer principle technology, PolyJet 3D Printer principle technology.

Q2: Which 3D Printer 3D printing principle technology is the most extensive?

FDM 3D printing technology is the most widely used because printing materials are cheaper than other printer technologies, and there are many types of materials, which can be applied in different fields such as artistic creation, product development, medical applications, architectural models, etc.

Q3: What is the principle of 3D Printer?

3D printing is widely used in various fields, so a variety of 3D printers with different materials have been developed. No matter what kind of technology, their 3D Printer principle is based on digital model files, matched with materials, and using different processing methods, such as sticking Combining, curing, fusion lamination, laser sintering and other processing methods, the materials are combined layer by layer, and finally the required finished product is produced.

License: The text of “What are the principles and technologies of 3D printers?” by 3D Lab Store is licensed under a Creative Commons Attribution 4.0 International License.

高速3D打印機組合-封面-1-450x450.jpg)