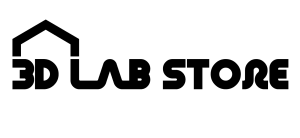

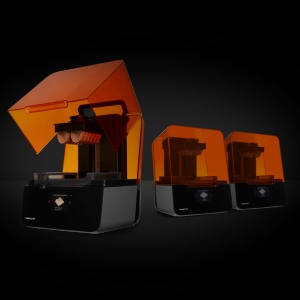

Formlabs Form 3 SLA 3D Printer

Formlabs Form 3 SLA 3D printer can consistently print 3D model with industrial quality and high accuracy.

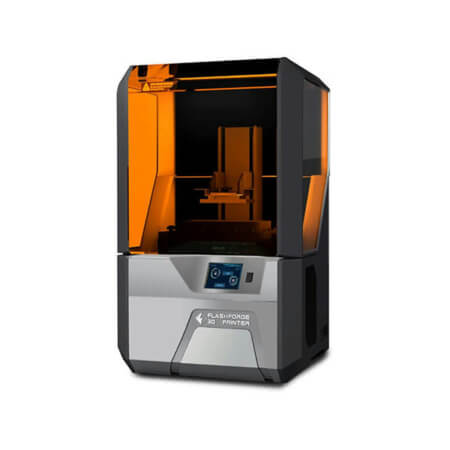

Industrial-quality Formlabs Form 3 SLA 3D printer is equipped with a new technology called LFS (Low Force Stereolithography) technology. This 3D printing method uses a flexible tank and linear illumination, which can dramatically improve print quality and repeatability by reducing peel forces. LFS technology allows Formlabs Form 3 SLA 3D printer to print a better part surfaces and easy support removal. It also makes it possible to 3D print complex materials such as high viscosity resins.

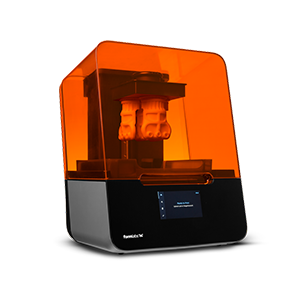

The custom-designed Light Processing Unit (LPU) inside the printer uses a compact system of lenses and mirrors to deliver accurate and repeatable prints. Light processing unit (LPU) of Industrial-quality Formlabs Form 3 SLA 3D printer has the high-power-density 250mW laser inside, which delivers highly precise prints. The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot. The module moves laterally below the resin tank, contrary to the usual fixed lasers or projectors that can be used on standard resin 3D printers.

Also, the user-replaceable components including light processing unit, rollers, and optics window can be replaced in-house, reducing the need for replacement printer shipments.

The industrial-quality Formlabs Form 3 SLA 3D printer enables you to have constant monitoring, which means you can constantly monitors its printing process, which means you can focus on bringing your most creative ideas to life, helping you in maintaining ideal print conditions and sending you alerts about the state of your machine. Formlabs Form 3’s various optical sensors also deliver a constant automatic calibration, and even able to detect if there is dust that you don’t want in the printer, which therefore to ensure you have an industrial-quality outcome.

Formlabs Form 3 SLA 3D printer provides a hassle-free materials and user-friendly cartridge system, which allows users to switch materials in seconds by simply replacing the resin cartridge. Also, users are not required to pour the resin into the tank manually.

Formlabs Form 3 Main Features:

– LFS (Low Force Stereolithography) technology

– Repeatable high-quality, high-precision 3D printing

– High power density laser

– Continuously monitor the printing process

– Automatic calibration

– User-friendly cartridge system

Regarding shipping policies, please refer to here.

Product Description

Formlabs Form 3 SLA 3D printer can consistently print 3D model with industrial quality and high accuracy.

Industrial-quality Formlabs Form 3 SLA 3D printer is equipped with a new technology called LFS (Low Force Stereolithography) technology. This 3D printing method uses a flexible tank and linear illumination, which can dramatically improve print quality and repeatability by reducing peel forces. LFS technology allows Formlabs Form 3 SLA 3D printer to print a better part surfaces and easy support removal. It also makes it possible to 3D print complex materials such as high viscosity resins.

The custom-designed Light Processing Unit (LPU) inside the printer uses a compact system of lenses and mirrors to deliver accurate and repeatable prints. Light processing unit (LPU) of Industrial-quality Formlabs Form 3 SLA 3D printer has the high-power-density 250mW laser inside, which delivers highly precise prints. The high-power-density laser is passed through a spatial filter to guarantee a clean laser spot. The module moves laterally below the resin tank, contrary to the usual fixed lasers or projectors that can be used on standard resin 3D printers.

Also, the user-replaceable components including light processing unit, rollers, and optics window can be replaced in-house, reducing the need for replacement printer shipments.

The industrial-quality Formlabs Form 3 SLA 3D printer enables you to have constant monitoring, which means you can constantly monitors its printing process, which means you can focus on bringing your most creative ideas to life, helping you in maintaining ideal print conditions and sending you alerts about the state of your machine. Formlabs Form 3’s various optical sensors also deliver a constant automatic calibration, and even able to detect if there is dust that you don’t want in the printer, which therefore to ensure you have an industrial-quality outcome.

Formlabs Form 3 SLA 3D printer provides a hassle-free materials and user-friendly cartridge system, which allows users to switch materials in seconds by simply replacing the resin cartridge. Also, users are not required to pour the resin into the tank manually.

Regarding shipping policies, please refer to here.

Product Main Features

Formlabs Form 3 Main Features:

– LFS (Low Force Stereolithography) technology

– Repeatable high-quality, high-precision 3D printing

– High power density laser

– Continuously monitor the printing process

– Automatic calibration

– User-friendly cartridge system