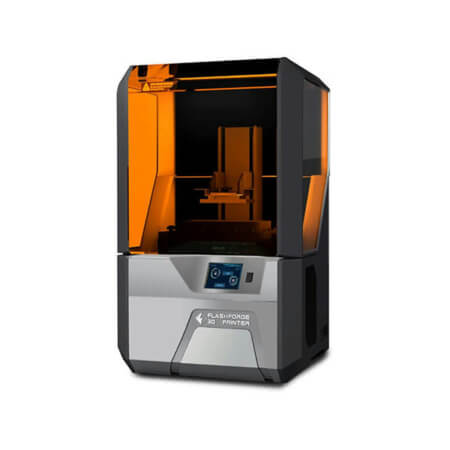

Flashforge Guider 3 3D Printer

Flashforge Guider 3, as a new generation of lightweight 3D printer, has characteristics such as larger print space ratio and convenient nozzle replacement. Equipped with the dual build plate options, quick-disassembly nozzle, HEPA 13 air filter, remote monitoring and other functions, it provides intelligent and convenient printing experience for education, small enterprises and individual users, making it a cost-effective choice for small batch production applications.

Flashforge Guider 3 3D Printer main functions:

- Lightweight Printer Larger Print Space

- Integrated Equipment Management System

- Real-time Monitoring of the Printing Process

- Power Loss Recovery System

- Open Material System

- Faster Delivery Capacity Offering Higher Production Efficiency

- More Convenient Leveling System

- Dual Platform Options for Individual Needs

- Quick-disassembly Nozzle

- Air Filter Net

- Ultra-silent Design

- Filament Run-out Reminder

- Cloud Platform

Lightweight Printer Larger Print Space

Compared with the Guider Ils series, Flashforge Guider 3 features larger print space and lighter equipment weight.

The entire frame adopts aluminum structure, and the enclosure adopts lightweight and durable ABS and acrylic sheets. On the premise of ensuring stability, this realizes the lightweight design from the inside out, and maximizes the use of the internal space as well, thus increasing the build volume.

The bigger and lighter Flashforge Guider 3 meets users’ diversified printing needs and daily use.

Integrated Equipment Management System

FlashPrint 5 enablesmulti-machine joint control and integrated device management in small batch production.

Real-time Monitoring of the Printing Process

With the camera equipped, the printing process and status can be monitored in real time easily through FlashPrint 5 and Ul interfaces.

Power Loss Recovery System

It can save the printing state in the event of an unexpected power failure and continue printing after the power is restored.

Open Material System

The 320°C high-temperature extruder is compatible withABS/PLA/PC/PA/HIPS/ASAPETG/PA-CF, etc., and supports third-party materials, suitable for various applications.

Faster Delivery Capacity Offering Higher Production Efficiency

With the CoreXY structure adopted, Flashforge Guider 3 supports high-speed printing of up to 300mm/s, realizing efficient production. Under the same conditions except speed, one Guider 3 can save about 30%-50% of the printing time. When in the small batch production mode, quick delivery can be completed, which greatly improves the efficiency.

More Convenient Leveling System

Leveling is the first step to start printing, and the flatness of the build plate is crucial to the success and quality of printing. Flashforge Guider 3 optimizes the automatic leveling system + auxiliary leveling to ensure your leveling operation in all directions. More worry-free leveling: Operate according to the system screen, which is clear at a glance. The high-sensitivity and inductive proximity sensor detects and save the initial flatness data of the horizontal platform, and intelligently compensates the platform height through Z-axis during the printing process to realize automatic leveling.

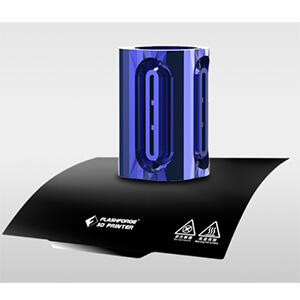

Dual Platform Options for Individual Needs

Flashforge Guider 3 offers two different platform options: glass platform and flexible steel plate platform. Thus, users can make personalized choices according to their needs when printing different filaments, which makes it suitable for diversified print scenes. Optimized platform design, realizing quick replacement within 30s; Uniform 110℃-heating over the whole format, offering better printing effects.

Quick-disassembly Nozzle

Suitable for various filaments, the double-gear extrusion structure design increases the filament feeding force by 150% and causes less clogging situations. The quick-disassembly nozzle, with multiple diameter options, is easy to replace and maintain, and can meet various use requirements.

Regarding shipping, please refer to here.

Product Description

Flashforge Guider 3, as a new generation of lightweight 3D printer, has characteristics such as larger print space ratio and convenient nozzle replacement. Equipped with the dual build plate options, quick-disassembly nozzle, HEPA 13 air filter, remote monitoring and other functions, it provides intelligent and convenient printing experience for education, small enterprises and individual users, making it a cost-effective choice for small batch production applications.

Lightweight Printer Larger Print Space

Compared with the Guider Ils series, Flashforge Guider 3 features larger print space and lighter equipment weight.

The entire frame adopts aluminum structure, and the enclosure adopts lightweight and durable ABS and acrylic sheets. On the premise of ensuring stability, this realizes the lightweight design from the inside out, and maximizes the use of the internal space as well, thus increasing the build volume.

The bigger and lighter Flashforge Guider 3 meets users’ diversified printing needs and daily use.

Integrated Equipment Management System

FlashPrint 5 enablesmulti-machine joint control and integrated device management in small batch production.

Real-time Monitoring of the Printing Process

With the camera equipped, the printing process and status can be monitored in real time easily through FlashPrint 5 and Ul interfaces.

Power Loss Recovery System

It can save the printing state in the event of an unexpected power failure and continue printing after the power is restored.

Open Material System

The 320°C high-temperature extruder is compatible withABS/PLA/PC/PA/HIPS/ASAPETG/PA-CF, etc., and supports third-party materials, suitable for various applications.

Faster Delivery Capacity Offering Higher Production Efficiency

With the CoreXY structure adopted, Flashforge Guider 3 supports high-speed printing of up to 300mm/s, realizing efficient production. Under the same conditions except speed, one Guider 3 can save about 30%-50% of the printing time. When in the small batch production mode, quick delivery can be completed, which greatly improves the efficiency.

More Convenient Leveling System

Leveling is the first step to start printing, and the flatness of the build plate is crucial to the success and quality of printing. Flashforge Guider 3 optimizes the automatic leveling system + auxiliary leveling to ensure your leveling operation in all directions. More worry-free leveling: Operate according to the system screen, which is clear at a glance. The high-sensitivity and inductive proximity sensor detects and save the initial flatness data of the horizontal platform, and intelligently compensates the platform height through Z-axis during the printing process to realize automatic leveling.

Dual Platform Options for Individual Needs

Flashforge Guider 3 offers two different platform options: glass platform and flexible steel plate platform. Thus, users can make personalized choices according to their needs when printing different filaments, which makes it suitable for diversified print scenes. Optimized platform design, realizing quick replacement within 30s; Uniform 110℃-heating over the whole format, offering better printing effects.

Quick-disassembly Nozzle

Suitable for various filaments, the double-gear extrusion structure design increases the filament feeding force by 150% and causes less clogging situations. The quick-disassembly nozzle, with multiple diameter options, is easy to replace and maintain, and can meet various use requirements.

Product Main Features

Flashforge Guider 3 3D Printer main functions:

– Lightweight Printer Larger Print Space

– Integrated Equipment Management System

– Real-time Monitoring of the Printing Process

– Power Loss Recovery System

– Open Material System

– Faster Delivery Capacity Offering Higher Production Efficiency

– More Convenient Leveling System

– Dual Platform Options for Individual Needs

– Quick-disassembly Nozzle

– Air Filter Net

– Ultra-silent Design

– Filament Run-out Reminder

– Cloud Platform