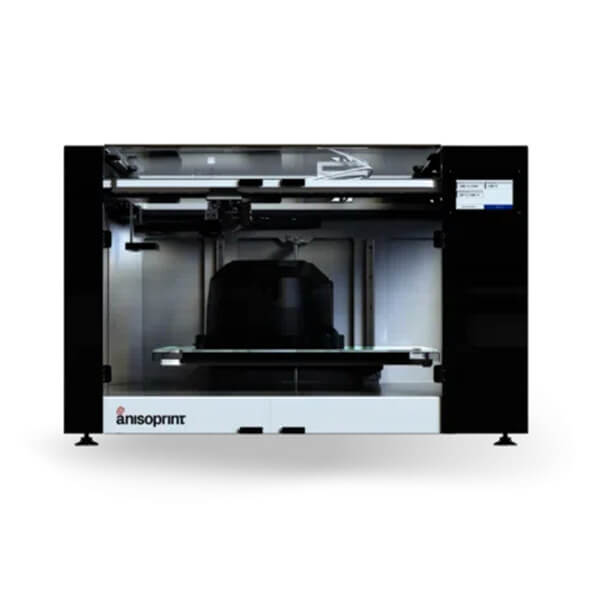

Anisoprint Composer A3 Continuous Carbon Fiber 3D Printer

Anisoprint Composer A3 is a continuous carbon fiber 3D printer. It works both with the patented CFC technology (Composite Fiber Coextrusion) and with standard FFF 3D printing technology. Composer A3 enables the production of optimized composite structures that are characterized by high physical and mechanical properties. The end parts are stronger and lighter than parts with similar properties that are made with metal, thermoplastics or non-optimized composites. They can also be manufactured at a lower cost.

Anisoprint Composer A3 continuous carbon fiber reinforced composites it’s 30 times stronger than pure plastic, 2 times stronger and lighter than aluminum. The optimal composite structures is lattice reinforcement – minimal weight, price and production time for the required strength

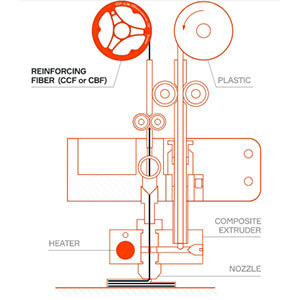

It is open material system: use any plastic (up to a melting temperature of 270 °C). The thermoplastic is reinforced with composite fibers during printing. The extruder has two inputs: one for reinforcing material and the other for the thermoplastic. Any plastic with a printing temperature of up to 270 ° C can be used (e.g. PETG, ABS, PC, PLA, nylon, etc.).

The strength and rigidity of the composite material lie along the fiber, which is why the grids, which consist of one-dimensional grid, represent the optimal shape for composite materials. The composite filling gives you maximum strength with minimal use of materials, i.e. minimal weight, minimal production time and minimal price of the printed component.

Anisoprint Composer A3 main functions:

- Composite Fiber Coextrusion (CFC)

- Dual printing head

- Able to optimize the internal structure of composite materials

- Anisoprint Aura slicer

- Open system

Product Description

Anisoprint Composer A3 is a continuous carbon fiber 3D printer. It works both with the patented CFC technology (Composite Fiber Coextrusion) and with standard FFF 3D printing technology. Composer A3 enables the production of optimized composite structures that are characterized by high physical and mechanical properties. The end parts are stronger and lighter than parts with similar properties that are made with metal, thermoplastics or non-optimized composites. They can also be manufactured at a lower cost.

Anisoprint Composer A3 continuous carbon fiber reinforced composites it’s 30 times stronger than pure plastic, 2 times stronger and lighter than aluminum. The optimal composite structures is lattice reinforcement – minimal weight, price and production time for the required strength

It is open material system: use any plastic (up to a melting temperature of 270 °C). The thermoplastic is reinforced with composite fibers during printing. The extruder has two inputs: one for reinforcing material and the other for the thermoplastic. Any plastic with a printing temperature of up to 270 ° C can be used (e.g. PETG, ABS, PC, PLA, nylon, etc.).

The strength and rigidity of the composite material lie along the fiber, which is why the grids, which consist of one-dimensional grid, represent the optimal shape for composite materials. The composite filling gives you maximum strength with minimal use of materials, i.e. minimal weight, minimal production time and minimal price of the printed component.

Product Main Features

Anisoprint Composer A3 main functions:

-Composite Fiber Coextrusion (CFC)

-Dual printing head

-Able to optimize the internal structure of composite materials

-Anisoprint Aura slicer

-Open system

Anisoprint Composer A3 Product Features

Composite Fiber Coextrusion (CFC)

Composite extruder has two inputs: one for the reinforcing fiber and the other for thermoplastic filament. It’s possible to print composite parts of complex shapes with lattice inner structure: use minimum material for required strength that means minimum weight, production time and price of a part.

Open system

Open system Flexible material selection, use of any plastic (melting temperature up to 270°C), adjustable fiber volume ratio, and free control of fiber laying path, so you can print complex shaped parts with lattice internal structure.

Optimal internal structure of composite materials

Allows users to use the least amount of material to meet the required strength, can effectively reduce consumables consumption, production time and cost.

Anisoprint Aura slicer

Anisoprint Aura slicer is designed for both continuous fiber 3D printing with proprietary CFC technology and conventional FFF-printing.

Anisoprint Composer A3 Product Specifications

Printer Model | Anisoprint Composer A3 |

Max Print Speed | For FFF: up to 80 mm/sec;

For CFC: up to 10 mm/sec;

|

Minimum Layer Height | 60 µm

|

Extruder Quantity | 2 |

Nozzle Size | 0.4 mm |

Nozzle | FFF extruder; CFC extruder with cutting device for reinforcing fibers

|

Maximum Printing Temperature | 270°C |

Maximum Build Plate Temperature | 60°С (up to 120°С with open pressure chamber)

|

Supported Materials | Plastics with processing temperatures up to 270℃, Anisoprint CCF-1.5k, CBF |

Filament Diameter | 1.75mm |

Build Volume | 460 L x 297 W x 210 H mm

|

Product Dimension | 720 L x 630 W x 490 H mm |

Build Plate | Glass

|

Connectivity | USB, SD card

|

Slicer | Anisoprint Aura (FFF+CFC)

|

Supported OS | Windows, Mac OSX, Linux

|