Roland MDX-50 CNC Milling Machine

The Roland MDX-50 CNC milling machine combines precise and automated milling, with automatic tool changer and built-in debris collection drawer. It is ideal to make short-runs and prototypes, the MDX-50 CNC milling machine reduces operation time and simplifies production so users of all abilities can mill functional parts with incredible quality on a wide range of materials.

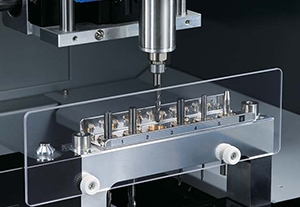

Automatic Tool Changer

The Roland MDX-50 CNC milling machine has 5-station Automatic Tool Changer for continuous operation without stopping to change milling tools. increases performance and operating speeds.

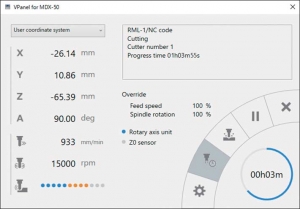

Operator-Friendly Control and Software

The MDX-50 CNC milling machine has a powerful built-in control panel and virtual control panel (VPanel). Its bundled SRP Player CAM software is easy-to-use and with simple operation.

Mill Fine Details and Smooth Finishes

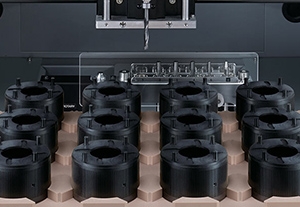

With an improved drive system the Roland MDX-50 CNC milling machine can make incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 400mm(X) x 305mm(Y) x 135mm(Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The built-in 5-station ATC and optional rotary axis unit can provide most automated and precise operation, which include auto-sensing function correcting the tool length to ensure milling accuracy for every job. The optional rotary axis can easily produce complex surfaces, including a wide, self-centering headstock and tailstock workpiece clamps, auto-rotates materials from 0-to-360 degrees, and indexes for 2-sided, 4-sided and custom angles

SRP Player CAM

MDX-50. Milling settings can be configured in five simple steps, making operation straightforward even for those new to milling. SRP Player CAM can support IGES、STL、DXFand 3DM ( Rhnio ) file format.