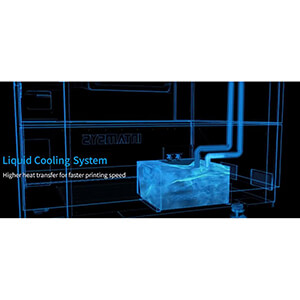

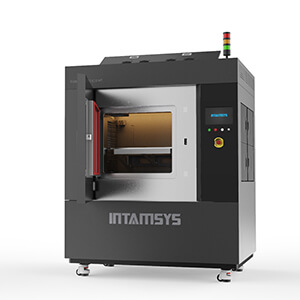

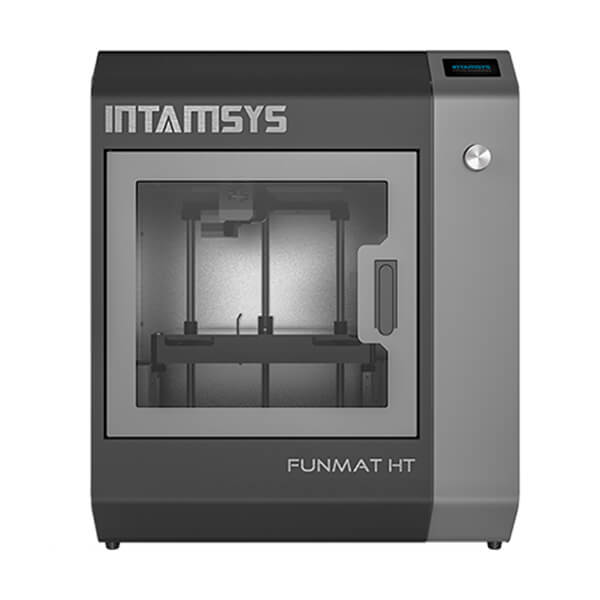

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer

INTAMSYS has paved a way with their breakthrough FUNMAT PRO 610 HT PEEK 3D Printer. Unlocking the potential of industrial-grade, high-quality 3D printing, equipped to effectively handle the tough requirements needed to print with high-performance thermoplastics. This Next-Generation in Large Scale FFF Printing Industrial 3D printing technology enables customers to print functional prototypes, tooling and end-use parts that optimize the entire design to manufacturing process. 3D printing technology has enabled customers to print end-use parts that are both lighter and stronger, while creating tools that have pushed the boundaries of industrial applications. Aerospace and automotive have been huge benefactors of 3D printing as well as early adopters of the end-use capabilities that 3D printing now provides. INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial 3D Printer saves up to 50% on material costs with our open material platform while allowing you to choose the best material for each application.

INTAMSYS FUNMAT PRO 610 HT main functions:

- Increased Efficiency

- Industrial Design

- Cost Effective

- High printing quality

- Production Graded System

- Advanced Thermal Design

- Safety Design

- Open Material System with Infinite Possibilities

- Auto-Cleaning Nozzles

- Filament Jam Warning

- Filament Absencel Warning

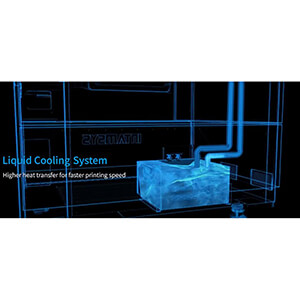

- Liquid Cooling System

- Vacuum Absorption Platform

- Over Heat Protection

- Automatic Filament Reloading

- Automatic Leveling

Advanced Thermal Design

Specialty high-temperature 3D print nozzles, up to 500°C and 300°C chamber temperature unlocks the ability to utilize advanced materials. This combination solves the issues of part warpage while offering consistent, quality parts every time.

High printing quality

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer has optimized 3D printing environment with an advanced servo control system provides you with premium print quality.

Consumable Drying System

The INTAMSYS FUNMAT PRO 610 HT PEEK 3D Printer unit is capable of placing 4 rolls of silk with an active drying system to ensure optimum printing quality.

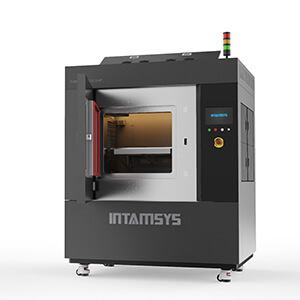

Liquid Cooling System

The INTAMSYS FUNMAT PRO 610 HT device has a liquid cooling system for better and faster temperature control for better printing results.

Open Material System with Infinite Possibilities

The INTAMSYS FUNMAT PRO 610 HT PEEK 3D Printer can support almost every high-performance thermoplastic material available on the market including PEEK, PEKK, PAEK, ULTEMTM, PPSU, PC, PA, ASA, ABS and others

Increased Efficiency

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer prints continuously with automatic filament reloading.

Safety Design

Best class safety components are equipped, CE(EMC/RED/LVT) certified for industry-grade application standard.

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer’s print volume up to 610 x 508 x 508mm(24x20x20in), allowing you to print large parts or multiple small parts for low volume production runs.

Regarding shipping, please refer to here.

Product Description

INTAMSYS has paved a way with their breakthrough FUNMAT PRO 610 HT PEEK 3D Printer. Unlocking the potential of industrial-grade, high-quality 3D printing, equipped to effectively handle the tough requirements needed to print with high-performance thermoplastics. This Next-Generation in Large Scale FFF Printing Industrial 3D printing technology enables customers to print functional prototypes, tooling and end-use parts that optimize the entire design to manufacturing process. 3D printing technology has enabled customers to print end-use parts that are both lighter and stronger, while creating tools that have pushed the boundaries of industrial applications. Aerospace and automotive have been huge benefactors of 3D printing as well as early adopters of the end-use capabilities that 3D printing now provides. INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial 3D Printer saves up to 50% on material costs with our open material platform while allowing you to choose the best material for each application.

Advanced Thermal Design

Specialty high-temperature 3D print nozzles, up to 500°C and 300°C chamber temperature unlocks the ability to utilize advanced materials. This combination solves the issues of part warpage while offering consistent, quality parts every time.

High printing quality

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer has optimized 3D printing environment with an advanced servo control system provides you with premium print quality.

Consumable Drying System

The INTAMSYS FUNMAT PRO 610 HT PEEK 3D Printer unit is capable of placing 4 rolls of silk with an active drying system to ensure optimum printing quality.

Liquid Cooling System

The INTAMSYS FUNMAT PRO 610 HT device has a liquid cooling system for better and faster temperature control for better printing results.

Open Material System with Infinite Possibilities

The INTAMSYS FUNMAT PRO 610 HT PEEK 3D Printer can support almost every high-performance thermoplastic material available on the market including PEEK, PEKK, PAEK, ULTEMTM, PPSU, PC, PA, ASA, ABS and others

Increased Efficiency

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer prints continuously with automatic filament reloading.

Safety Design

Best class safety components are equipped, CE(EMC/RED/LVT) certified for industry-grade application standard.

INTAMSYS FUNMAT PRO 610HT Large Build Volume Industrial PEEK 3D Printer’s print volume up to 610 x 508 x 508mm(24x20x20in), allowing you to print large parts or multiple small parts for low volume production runs.

Product Main Features

INTAMSYS FUNMAT PRO 610 HT main functions:

– Increased Efficiency

– Industrial Design

– Cost Effective

– High printing quality

– Production Graded System

– Advanced Thermal Design

– Safety Design

– Open Material System with Infinite Possibilities

– Auto-Cleaning Nozzles

– Filament Jam Warning

– Filament Absence Warning

– Liquid Cooling System

– Vacuum Absorption Platform

– Over Heat Protection

– Automatic Filament Reloading

– Automatic Leveling