Felix Pro L Large Volume 3D Printer

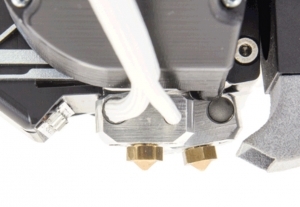

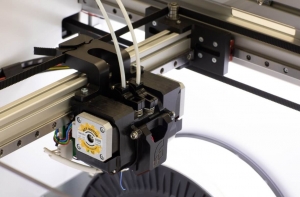

The FELIX Pro L is manufactured by Dutch manufacturer FELIXprinters. It has been constructed to ensure reliable output for much larger 3D printed parts. These are manufacturing tools for product development and manufacturing.

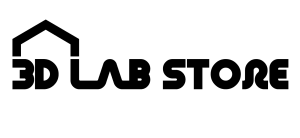

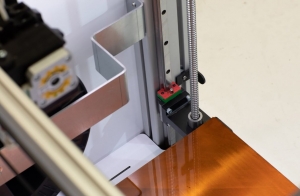

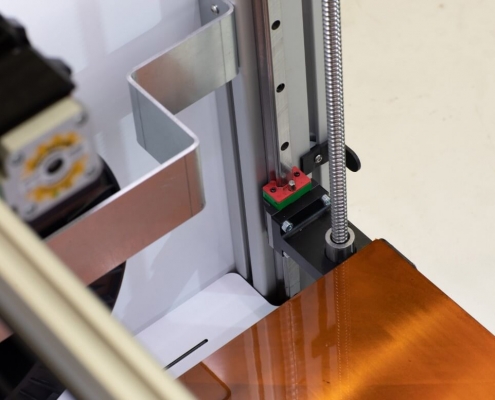

It features an advanced dual head system with which the second nozzle can be flipped back when the first nozzle active and printing. The advantage of the flipping mechanism can prevent the material leakage from non-used extruders on the printed object, and prevent collision of non-used extruder with the printed object.

FELIX Pro L Main Features:

- Large printing size up to 300 L x 400 W x 400 H mm

- Embedded UPS power system

- Fully automatic calibration

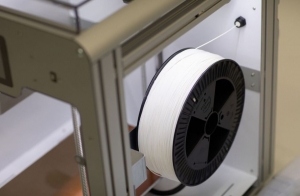

- Able to load up to 3kg filament

- Embedded filament detection sensor

- Removable and flexible metal heat bed

- Low operation noises

- Kevlar fibre reinforced belt

The team behind the FELIX Pro L Large Volume Dual Nozzle 3D Printer bring together many years of engineering and 3D printing experience to overcome the difficulties that many 3D printer users encounter during 3D printing. The results can be found in the Pro L through its robust construction, automated features, ease of use, incredibly low noise emissions and print quality.

On the other hand, this product comes with a professional slicing software Simplify 3D for free.

Regarding shipping policies, please refer to here

Product Description

The FELIX Pro L is manufactured by Dutch manufacturer FELIXprinters. It has been constructed to ensure reliable output for much larger 3D printed parts. These are manufacturing tools for product development and manufacturing.

It features an advanced dual head system with which the second nozzle can be flipped back when the first nozzle active and printing. The advantage of the flipping mechanism can prevent the material leakage from non-used extruders on the printed object, and prevent collision of non-used extruder with the printed object.

The team behind the FELIX Pro L Large Volume Dual Nozzle 3D Printer bring together many years of engineering and 3D printing experience to overcome the difficulties that many 3D printer users encounter during 3D printing. The results can be found in the Pro L through its robust construction, automated features, ease of use, incredibly low noise emissions and print quality.

On the other hand, this product comes with a professional slicing software Simplify 3D for free.

Regarding shipping policies, please refer to here

Product Main Features

FELIX Pro L Main Features:

– Large printing size up to 300 L x 400 W x 400 H mm

– Embedded UPS power system

– Fully automatic calibration

– Able to load up to 3kg filament

– Embedded filament detection sensor

– Removable and flexible metal heat bed

– Low operation noises

– Kevlar fibre reinforced belt