Comparison between the latest water-soluble materials BVOH and PVA

When it comes to water-soluble support materials, people may think of PVA, but recently, another water-soluble material called BVOH has emerged. So what are the differences between water-soluble materials BVOH and PVA?

PVA printing material (or polyvinyl acetate) is the most traditional water-soluble material. It is the first soluble substance that appeared. However, it is relatively difficult to print, and it is not compatible with many printing materials. To improve this situation, researchers have been committed to innovating and developing new soluble 3D printing materials. Now, one of the new soluble materials is BVOH, a copolymer of vinyl alcohol. It has some functions that PVA did not have in the past, which allows it to be printed more easily and compatible with more materials. Let’s take a look at the differences between the two!

Why use water-soluble materials

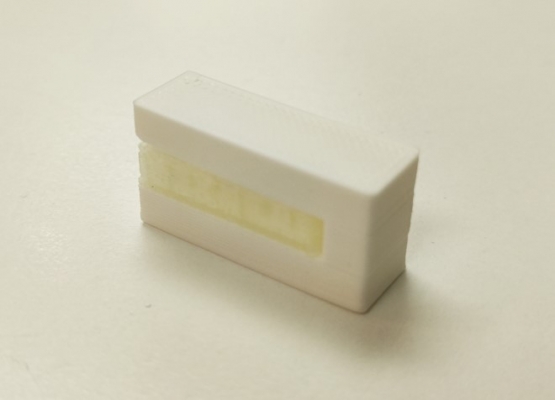

When printing 3D models, there are often overhanging parts that need to be supported to be printed. In the past, a 3D printer with only one nozzle could only use the same material to print support parts. However, with a dual-nozzle 3D printer, water-soluble printing materials can be used for support. The advantage of using water-soluble materials for support is that it saves labor to remove the support, and the contact between the support and the overhanging part has a better printing effect. On the other hand, it is very difficult to manually cut and remove the support for overhanging parts that are deeply embedded in the model. But if water-soluble support is used, it will be much more convenient.

Solubility

The most typical feature of BVOH and PVA is that they can be dissolved in water. But the first difference between them is that BVOH dissolves faster in water than PVA. The amount of residual BVOH in the 3D printed product is also relatively low.

The following is a comparison of the water solubility between BVOH and PVA:

Of course, there are many other factors that affect the time required for dissolution, such as water flow, temperature, and amount. But from the video, you can see that the dissolution speed of BVOH is faster than that of PVA when the two materials are in the same amount and still water, which can enable users to obtain printed products faster.

Compatibility with other printing materials

Although PVA is very common, it does not mean that it can be compatible with other commonly used materials. Currently, PVA can only effectively be compatible with PLA. In contrast, BVOH can be compatible with more printing materials, such as ABS, PETG, and even emerging engineering materials such as PAHT.

Compatibility means that PVA or BVOH can bond well with another material.

The following shows the compatibility of BVOH and ABS, for example, BVOH can stick to ABS and ABS can also stick to BVOH. If they are not compatible (such as PP and BVOH), they cannot be bonded to each other, resulting in printing failure.

| PVA | BVOH | |

| PLA | ✔ | ✔ |

| PETG | – | ✔ |

| TPU | – | ✔ |

| ABS | – | ✔ |

| PA | – | ✔ |

| PAHT | – | ✔ |

| PVA | BVOH | |

| PLA | ✔ | ✔ |

| PETG | – | ✔ |

| TPU | – | ✔ |

| ABS | – | ✔ |

| PA | – | ✔ |

| PAHT | – | ✔ |

As shown in the table above, BVOH can be compatible with six types of materials, while PVA can only be compatible with one type. It can be inferred that in the future, the use of BVOH will become more extensive than PVA.

Hygroscopicity and degradation

All water-soluble materials have the ability to absorb moisture and degrade over time. Depending on the material, the rate may change drastically.

Due to its thermal properties, PVA has a high hygroscopicity and is easy to degrade, so it is not recommended for long-term printing to avoid the material being affected by the heat emitted by the printer. BVOH also has a high moisture absorption rate, but due to its structure having higher temperature resistance, the degree of degradation will be less. Even for continuous two-day printing time in a 3D printer with enclosed printing space, such as the Flashforge Creator 4 or BCN3D Epsilon W50 , there will be no problems.

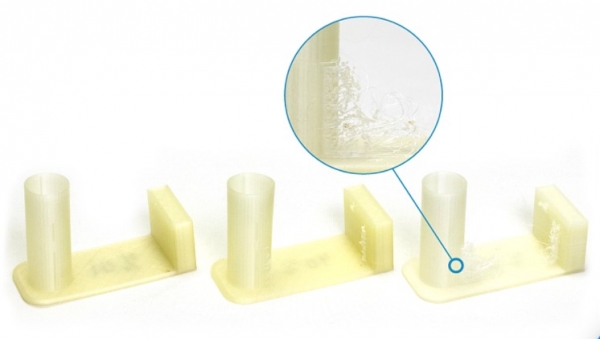

It is precisely because of the above reasons that many people also encounter the problem of not being able to use the material after it is opened due to the moisture absorption of the water-soluble material. However, as long as we store it properly, these water-soluble materials can still be stored for a period of time without causing waste. You can purchase a special material storage box for your water-soluble materials. These boxes generally come with moisture-proof features.

Image source: BCN3D

Printing difficulty

Each material has its own printing difficulty, but it is well known that PVA is one of the most difficult 3D printing materials to print. PVA water-soluble 3D printing materials have two main problems. The first is that it is prone to stringing, and the second is that it is prone to nozzle clogging. In the first case, BVOH printing material is easier to print than PVA because its unique material structure reduces the possibility of stringing, which also ensures that extrusion becomes easier when using BVOH. A smoother printing process can further reduce the second problem mentioned above and ensure that the printing nozzle is not easily clogged.

Therefore, compared to PVA, BVOH is easier to print, can be compatible with more materials, and is not so susceptible to moisture that affects print quality.